High Accuracy Gantry Control

Our gantry control feature optimizes gantry motion systems for peak performance and mechanical reliability.

This advanced feature harnesses the power of the TransnET real-time communication bus to synchronize data across multiple axes, ensuring precise control tailored to the stage position.

By maximizing motion efficiency and bolstering mechanical integrity, our gantry control feature offers several key advantages.

Characteristics

- Advanced multi-axes control of gantry architectures

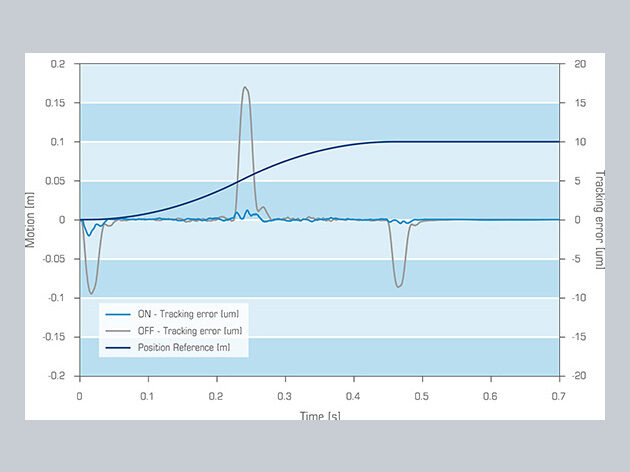

- Reduces settling-time thanks to adaptive feedforward

- Improves precisions and repeatability of gantry systems

AccurET’s gantry control feature

Here are the key features:

Enhanced mechanical reliability ensures consistent motion performance at any tool point location, ensuring reliable operation over extended periods.

Optimizing control algorithms ensures precise positioning with extremely low tracking error during motion, maintaining accuracy even in demanding operating conditions.

Minimizing “in-window” time enhances processing speed and productivity, while reducing vibrations during and after motion ensures smoother operation and improved efficiency.

Utilizing real-time data sharing among axes enables synchronized control, seamlessly integrating with other ETEL motion control features to maximize system performance.

By combining precision control with mechanical optimization, our gantry control feature empowers motion systems to operate at their peak, delivering reliability, accuracy, and efficiency in diverse industrial applications.