Nicolas Wavre, a visionary in the field of technology and innovation, has left a lasting mark on the industry by developing ETEL from a start-up into an international company.

In this article, we provide an overview of his passion for technology, his impressive career, and his ongoing connection with the sector.

The origin of a passion for technology, innovation, and development

Nicolas Wavre’s passion for technology began at an early age. “My father built his first car with his brother at the age of 16 in 1916, at a time when only doctors and notaries in Neuchâtel owned cars,” he recalls. “He was an engineer and a visionary, passionate about mechanics, and that way of being influenced me.” This early exposure to technical innovation laid the foundation for Nicolas Wavre’s later career.

Early career and the founding of ETEL

After graduating from EPFL in 1969, he embarked on a doctoral thesis focused on the study of electromagnetic fields in linear induction motors under the supervision of Prof. Marcel Jufer. In June 1974, he, along with Prof. Jufer and other partners and professors, founded ETEL S.A. in St-Sulpice (VD). The early years were extremely challenging but also very formative. “We didn’t have a product catalog, but we knew we could do anything,” he explains with a smile. With Professor Jufer, who was a virtuoso in electromagnetic calculation, they offered truly innovative solutions based on the principle of direct drive. “At the same time, I was able to build a very good team of young engineers at ETEL, which was a wonderful human experience. Together, we built a true industrial production tool thanks to everyone’s commitment and motivation.”

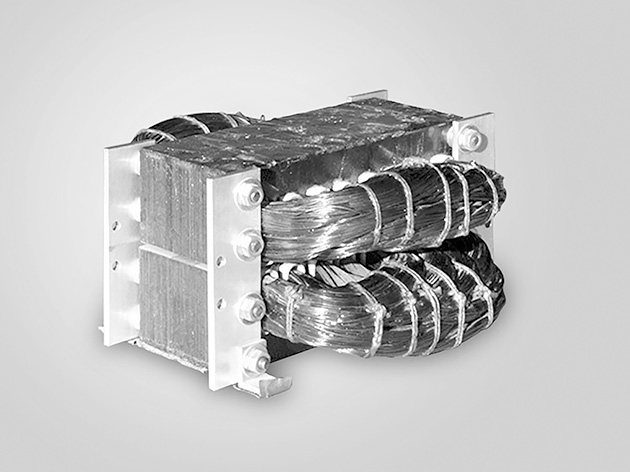

The beginning of ETEL, a linear motor.

ETEL’s developments

In the 1980s, ETEL developed rotary and linear motors for the European space sector (ESA) and applications for NASA. “We have motors literally everywhere in space,” Nicolas Wavre notes with a smile. Starting from 1988 onwards, ETEL’s production took off, and the company gained an international reputation by producing the first torque and linear motors applied to the medical and industrial markets. For machine tools, direct drive caused a quantum leap in machining precision. Simultaneously, linear motors achieved positioning accuracies in the nanometer range, contributing to the rapid development of the semiconductor industry. These technological breakthroughs made ETEL indispensable in the sector.

Nicolas Wavre, Founder of ETEL

“We didn’t have a product catalog, but we knew we could do anything.”

A life dedicated to innovation

Even after retiring from ETEL in 2004, Nicolas Wavre remains connected to the sector. “I advise many start-ups because the problems often remain the same as before: human, financial, strategic challenges, etc.,” he explains. “My experience can often help.” He emphasizes the importance of an adequate strategy and qualified human resources. Today, at 78 years, Nicolas Wavre is still active on boards of directors and remains a valuable mentor for young companies.

Dr. Wavre’s impressive career and unwavering commitment to innovation have made ETEL a leading company. His story is an inspiration and shows how passion and tenacity can lead to major technological advances.