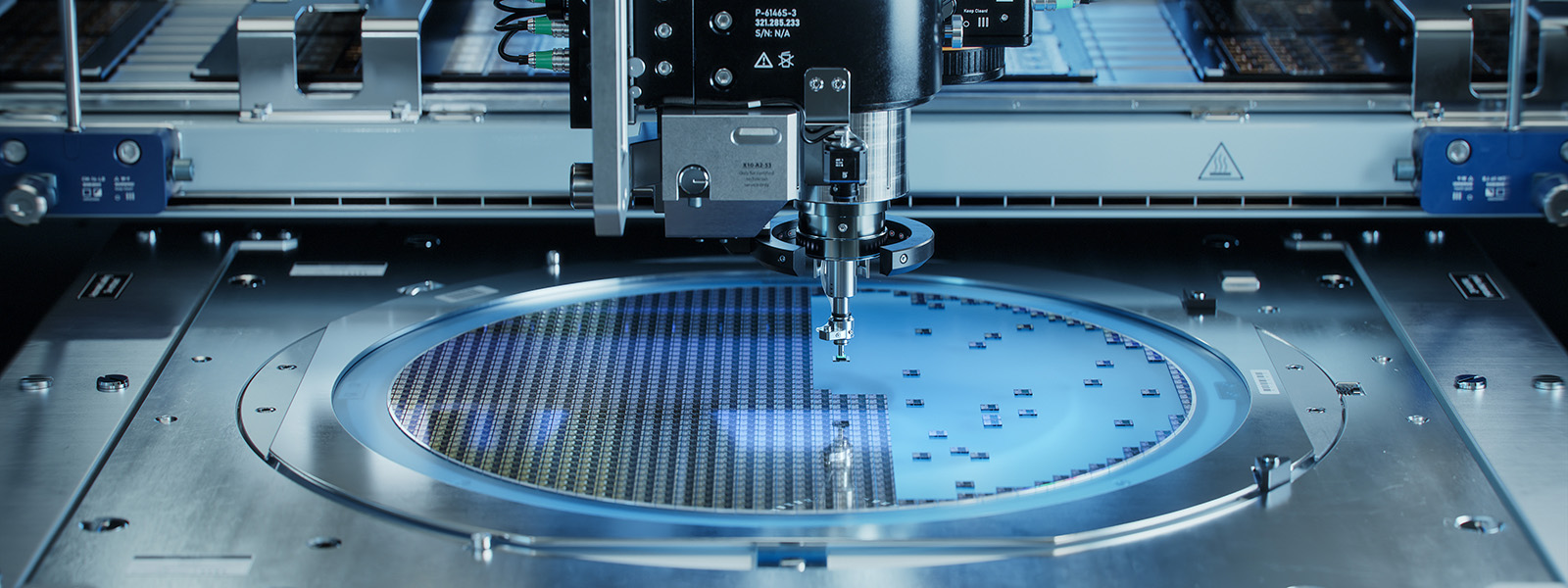

Pick and place

Pick-and-place machines are an essential component of the assembly process for electronic components on printed circuit boards (PCBs). The versatility of the process is required to handle different component sizes, shapes and packaging.

The efficient handling of different components sizes, shapes and packagings requires machines that are able to take these differences into account and adapt assembly strategies accordingly. Accurate monitoring of the trajectories is essential to avoid collisions and optimise dynamics.

ETEL provides application support services to ensure flawless integration of our systems into machine environments.

We also offer best in class electronics enabling high throughput, high accuracy thanks to advanced mapping functionality, on the fly camera management with real time position trigger, advanced force control to place fragile components, etc.

Position controllers

Do not hesitate to contact us to find out more about ETEL’s innovative and precise solutions.