Markets & Applications

ETEL is a leading supplier of a wide range of solutions, from individual components and standalone electronics to complete motion systems. We also offer application-oriented support and customised designs tailored to specific requirements and applications.

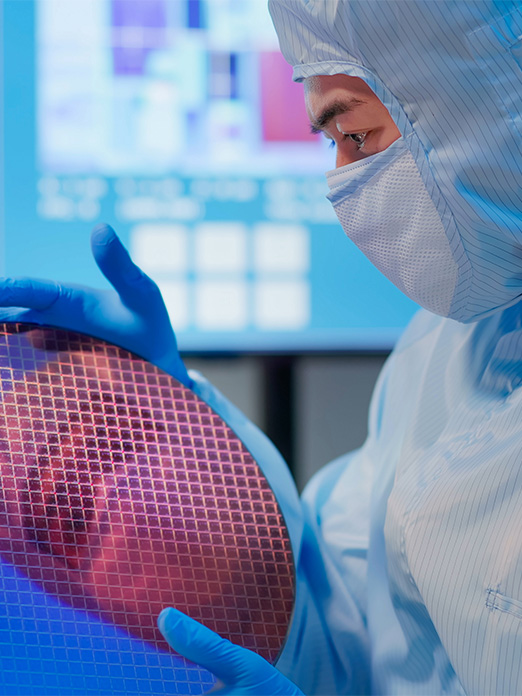

Semiconductor

Semiconductors are the foundation of all electronic devices. Our motion systems play a central role in driving innovation and efficiency to meet the demands of precision, throughput and reliability.

ETEL’s motion systems are trusted by semiconductor manufacturers worldwide to deliver exceptional performance and drive the future of technology forward.

When it comes to wafer processing, maintaining optimal performance throughout the production process is essential to ensure the quality and reliability of the semiconductor devices.

Achieving precise and uniform heating during laser annealing is a major challenge. However, it is essential for a successful semiconductor process.

When precision is paramount, ETEL delivers comprehensive solutions to ensure testing reliability, offering accuracy, high throughput, and stiffness.

Dicing is primarily about maintaining the integrity and functionality of the individualised components. In addition, chipping, cracks or other deformations of the sensitive chip structures should be avoided.

Die bonding, also known as die attach, is a crucial process in semiconductor manufacturing where a semiconductor chip, known as a die, is attached to a substrate or package.

Final testing in the semiconductor market is crucial to ensure chips function and their quality standards. It helps detecting any defects or flaws that may have occurred during manufacturing…

Electronics

Electronics is the backbone of modern society and brings together a wide range of devices and systems that are important for technological progress. From PCB manufacturing to final product testing, key players rely on our motion control because they are characterised by precise force control, high speed and reliability.

PCB manufacturing involves creating printed circuit boards, which serve as the foundation for electronic devices by providing electrical connections between components.

Pick and place machines are fundamental to the assembly of electronic components onto printed circuit boards (PCBs). The versatility of the process is required to handle…

Automated Optical Inspection (AOI) is a critical step in electronic manufacturing, aimed at detecting defects and ensuring the quality of assembled printed circuit boards (PCBs).

Ensuring product integrity is paramount in the electronics industry, and final testing procedures play a critical role in this process.

Machine tools

The demand for precision in mechanical parts has surged in recent decades, driving continuous innovation and process enhancements across the supply chain. ETEL’s motors are renowned for their robustness, maintenance-free operation, and compact design and offer the optimal solution for achieving the highest level of performance in this demanding industry. With our global Application Support teams and advanced simulation tools, we ensure you receive the perfect product fit for your application, without unnecessary safety margins, bolstering your success in the competitive landscape.

Precision is paramount in milling applications, and ETEL’s cutting-edge torque motors play a vital role in achieving unparalleled levels of accuracy.

For mill/turn machines demanding precision and speed, ETEL provides motors tailored to meet these dual requirements effectively.

Grinding stands as one of the most exacting segments in the machine tool industry, where precision is paramount.

Due to its unrivalled accuracy, laser processing has established itself as the first choice for precision cutting in various industries such as the automotive industry and medical technology.

Other

Other markets and process applications such as medical, printing, windmill, etc. complement our offering.

Medical imaging scanners including X-rays, CT scans and MRIs. The most commonly used drive systems are gear-based solutions that generate acoustic noise, limited life and limited accuracy.

The main challenges in the printing industry are speed and quality. Thanks to our direct drive solution (torque motor, linear motor and controller), these two performances can be combined.