Motion systems

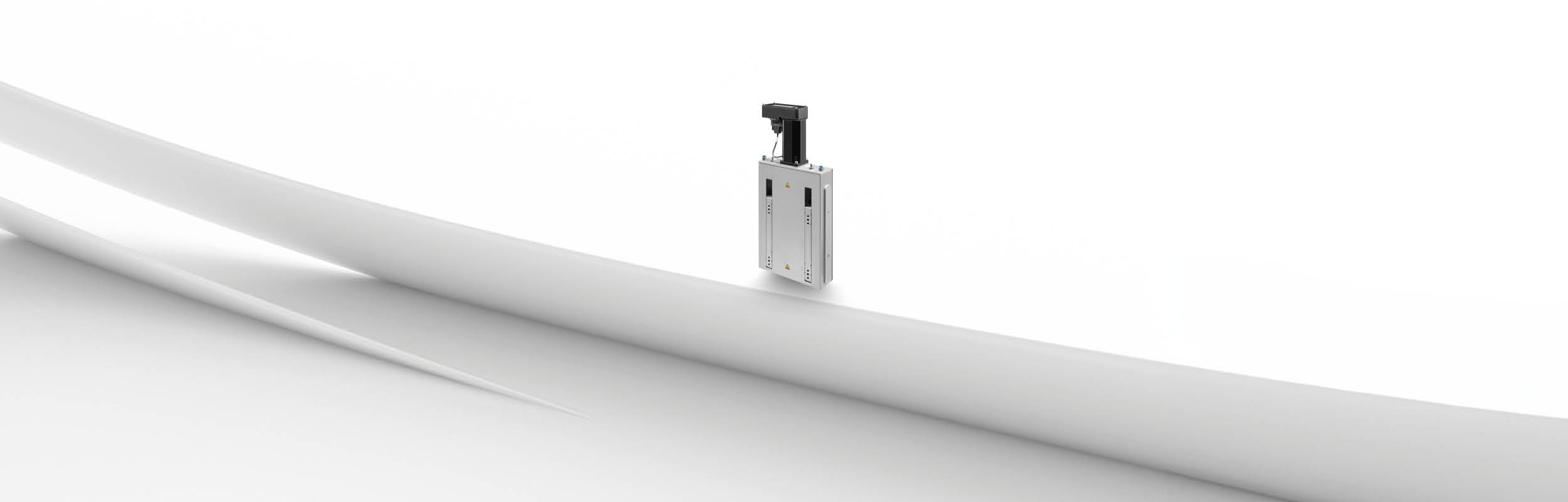

TBS

The TBS linear axis by ETEL offers unparalleled precision and performance, making it the ideal solution for high accuracy applications across diverse industries. The TBS is a high-precision linear axis with 1 Degree Of Freedom, utilizing a mechanical bearing-based indirect drive system. This design provides exceptional accuracy and precision within its category. Controlled by a high-performance,…

Show product